After ReduX Converter ReduX Technologies proudly presents a world novelty in energy production

MORF MOLECULAR REFRACTOR – MOLECULES TRANSFORMED IN ENERGY

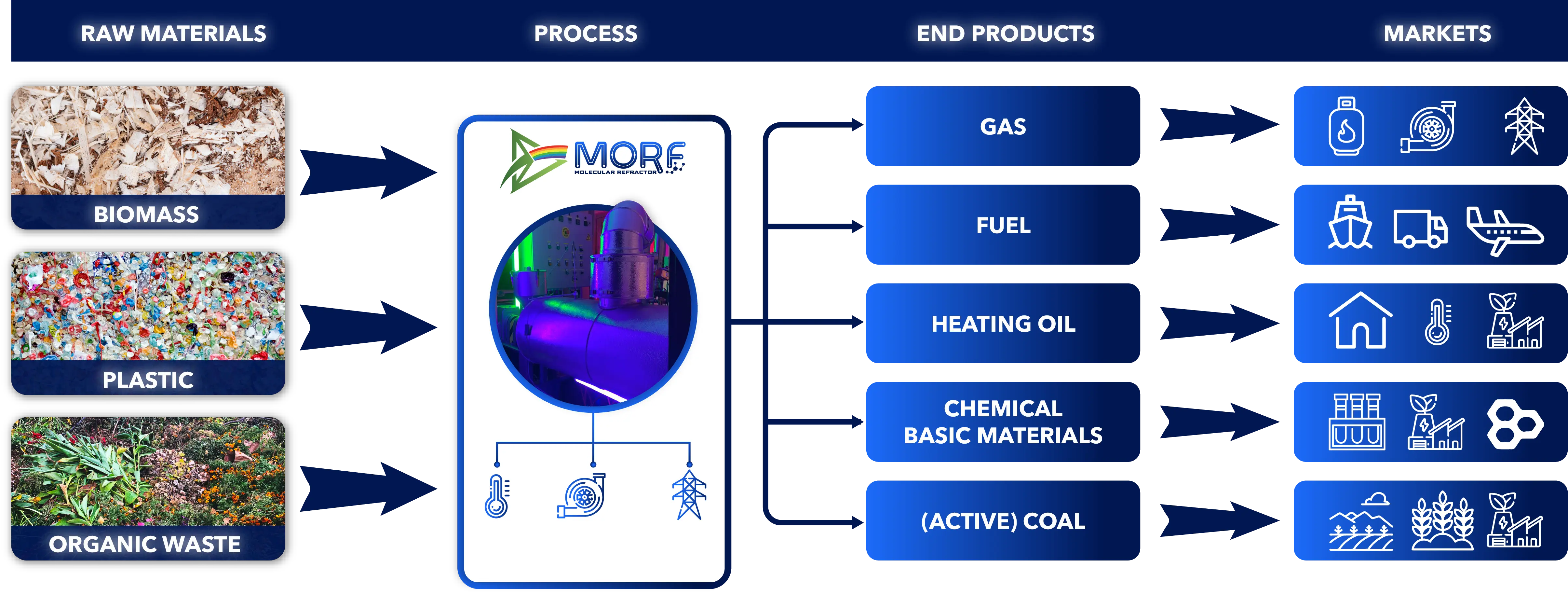

The MORF PROCESS is based on the CONCEPT of Molecular Refraction: this allows the use of a very wide range of residual materials such as biomass, organic matter, waste oil, sludge, plastic waste, etc. and converts them into high-quality fuels, gas and coal. Low-grade organic residues can thus be industrially refracted into high-grade energy sources. The separated carbon is bound as a long-term CO2 reservoir and the production process is therefore CO2 negative.

A PROCESS THAT NORMALLY TAKES MILLIONS OF YEARS IS CARRIED OUT WITHIN MINUTES AT MORF.

The extracted solid (depending on the residual material 5 - 35 %) remains bound in carbon and can be used as black earth or chemical products as CO2 storage.

Conclusion: MORF technology extracts the energy sources in gaseous, liquid form and the separated solid carbon is bound long-term as a biological or chemical base material (CO2 sink). The process is therefore CO2 negative instead of thermal utilization by burning e.g. residual wood, which is known as CO2 neutral.

Input materials: MORF efficiently refractions all carbon waste into high-quality and storable gaseous and liquid energy carriers.The products are technically very similar to the products from fossil origin and differ only in their origin.

Energy products: Thanks to the patented MORF process, these synthetic energy sources are the alternative for all combustion engines and can also be added to fossil fuels without any restrictions.

CO2 bounded products: The high-quality carbon that is separated out can be used as biochar (e.g. from biomass) or as a chemical raw material (e.g. from residues of fossil origin).

MORF technology is scalable (250 kg/h and 1000 kg/h are standard sizes) and several production lines with different material cycles can be operated.

The circular economy for waste materials, which today are only used thermally, can for the first time be converted into storable, high-calorific energy sources with the MORF technology.

USP of MORF technology vs. biomass utilization by wood cogeneration plants with thermal utilization: